Copyright 2025 CEBB H.F. Technology® | All rights reserved |

https://www.iubenda.com/api/privacy-policy/43326266https://www.iubenda.com/api/termini-e-condizioni/43326266https://www.iubenda.com/api/termini-e-condizioni/43326266

Technology

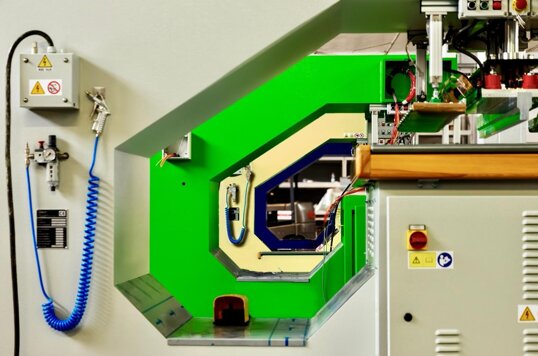

High-frequency welders are machines designed for packaging materials based on PVC (polyvinyl chloride), mainly used in the form of large sheets or tarpaulins.

The sturdiness of the machine and all the electromechanical and pneumatic components used in its construction, which comply with regulations and are largely oversized, give the welders a high degree of reliability.

Proper logistical support makes it possible to minimize the risk of machine downtime, thus ensuring programmable production with extremely low risks.

These are therefore devices designed to operate safely, in accordance with current EEC directives regarding machines with a medium-low risk level.

The technology used by these machines is based on 3 fundamental parameters:

- Pressure

- Power

- Time

The material to be welded is placed on the work surface, it is pressedby the welding electrode to which a power (or welding current) at high frequency (27.12 MHz) is applied, for a defined time .

The material thus becomes the high-loss insulator of a capacitor in which the POSITIVE pole is constituted by the WELDING ELECTRODE (OR MOLD), and the NEGATIVE pole by the work surface.

The PVC molecules, crossed by the high-frequency current, bond together to form a single body.

By mixing these 3 parameters, PRESSURE, POWER, TIME, it is possible to achieve excellent welding quality.

Thanks to this special technology, HIGH FREQUENCY JOINING of PVC sheets is by far the best possible welding for this product.

Copyright 2025 CEBB H.F. Technology® | All rights reserved |